Technical sheets

Aluminium wire

Product description

Aluminium-Silicon basis solid wire for GMAW and GTAW aluminium alloys welding.

Applications

Excellent surface finish. High resistance to cracks on the weld metal when combined with base materials of the 6000 series. Iron/metalwork, bicycles, motorbikes, automotive industry, air extraction facilities.

Classification

| EN ISO 18273 | S Al 4043 (AlSi5) |

|---|---|

| AWS/SFA-5.10/5.10M | ER 4043 |

| UNS | A94043 |

| ISO TR 17671-4 / EN 1011-4 | Type 4 |

| ASME IX | F-Nº23 (QW-432) |

Approvals

| Vd TÜV 1153 | DB N. 61.254.01 | CE N. 0035-CPR-C616 |

|---|

Chemical composition (weight %)

Chemistry according to EN ISO 18273. Individual values indicated in the table are maximum values.

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Be | Al |

|---|---|---|---|---|---|---|---|---|

| 4,5-6,0 | 0,60 | 0,30 | 0,15 | 0,20 | 0,10 | 0,15 | 0,0003 | Rest./Bal. |

Mechanical properties, typical as weld

Mechanical properties of the deposited metal are determined by the dilution with the base material.

| Gas | Temp. | Condition | Yield Strength 0,2% | Tensile Strength | Elongation | |

|---|---|---|---|---|---|---|

| Values acc. to DIN 1732-3 | I1 | 20ºC | As welded | ≥ 120 N/mm2 | ≥ 250 N/mm2 | ≥ 18% |

Usual base materials to be welded

Suitable for cast aluminium welding and cast aluminium welding when joining products of the series 3000, 5000, 6000, 7000. Products of series 3000, 5000, 6000.

Packaging

| Product | Size (Ø mm) |

|---|---|

| Plastic spools, Baskets and Drums | GMAW 1-1.20 – 1. 60 GTAW 2.4-3.2 |

Almacenamiento

Keep protected from humidity and dirt. Once the package is opened, and in case of not using all the material, keep into its original case closed and preferably in a heated cabinet, at least at 20°C. Keep the label of the spool (GMAW) or wrapping (GTAW).

Before welding

Remove the alumina layer and dirt (grease, dust…) as well as humidity from the welding area mechanically or by brushing it with stainless steel spikes. Do not use lubricant that contains diluted oils in the joints.

Welding equipment

When welding GMAW, conducts (liners, etc.) and pushing rollers have to be suitable for aluminum and be kept clean. Do not hit the gas outlet nozzle.

Welding conditions

| Thickness | Temperature | |

|---|---|---|

| Preheating | ≥ 10 mm | Start : 90-110ºC |

| Interpass | All thickness | Max. 110ºC |

Shielding gas

Inert gas : Ar 100%, Ar-He mixture

EN ISO 14175: I1

Flow = 14-18 L/min

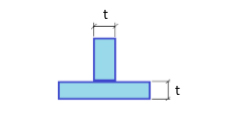

Welding positions

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| EN ISO 6947 | PA | PB | PC | PD | PE | PF |

| ASME IX | 1G | 2F | 2G | 4F | 4G | 3G ↑ |

Type of current & polarity

GMAW: Direct current, electrode to positive terminal: DC.E+ (Applicable modes: pulsed & not pulsed).

GTAW: Altern current, (Applicable modes: pulsed & not pulsed).

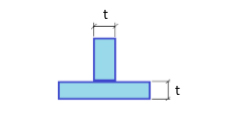

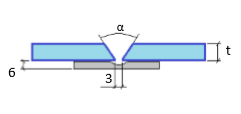

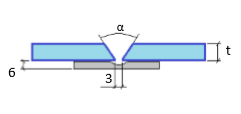

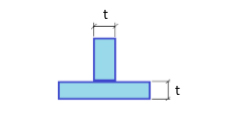

Recommended welding parameters for GMAW (pulsed)

These parameters may vary slightly depending on the welding unit.

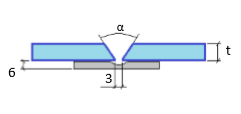

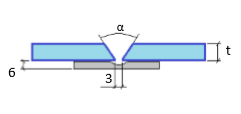

ø 1,0 mm

| Union | Param.* | Welding position | |

|---|---|---|---|

| All positions | |||

|

BW t ≤ 3mm | Int. (A) | 110-130 |

| Volt. (V) | 20-22 | ||

|

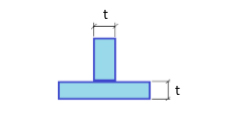

FW t ≤ 3mm | Int. (A) | 110-130 |

| Volt. (V) | 20-22 | ||

ø 1,2 mm

| Union | Param.* | Welding position | ||||||

|---|---|---|---|---|---|---|---|---|

| PA 1G | PB 2F | PC 2G | PD 4F | PE 4G | PF 3G ↑ | |||

|

BW mb t ≤ 3mm | Int. (A) | 140-150 | - | 140-150 | - | 140-150 | 130-140 |

| Volt. (V) | 21-22 | - | 21-22 | - | 21-22 | 21-23 | ||

|

BW mb t > 3mm t ≤ 8mm | Int. (A) | 160-180 | - | 150-170 | - | 150-170 | 140-160 |

| Volt. (V) | 22-24 | - | 21-23 | - | 21-23 | 23-24 | ||

| BW mb t > 8mm | Int. (A) | 180-220 | - | 170-180 | - | 180-220 | 140-200 | |

| Volt. (V) | 23-25 | - | 23-24 | - | 23-25 | 23-24 | ||

|

FW t ≤ 3mm | Int. (A) | 130-140 | |||||

| Volt. (V) | 21-23 | |||||||

| FW t > 3mm t ≤ 8mm | Int. (A) | 150-170 | ||||||

| Volt. (V) | 21-23 | |||||||

| FW t > 8mm | Int. (A) | 180-220 | 170-190 | 200-220 | 200-220 | 140-180 | ||

| Volt. (V) | 23-25 | 23-24 | 23-25 | 23-25 | 23-24 | |||

ø 1,6mm

| Union | Param.* | Posición soldeo | ||||||

|---|---|---|---|---|---|---|---|---|

| PA 1G | PB 2F | PC 2G | PD 4F | PE 4G | PF 3G ↑ | |||

|

BW mb t > 5mm | Int. (A) | 280-330--- | |||||

| Volt. (V) | 26-29 --- | |||||||

|

FW t > 5mm | Int. (A) | 280-330 | |||||

| Volt. (V) | 26-29 | |||||||

*Parameters for pulsed current.

Aluminium wire

Product description

Aluminium-Magnesium basis solid wire for GMAW and GTAW aluminium alloys welding.

Applications

Weldings where a high tensile strength is needed. More common welding alloy within Al-Mg family.

Classification

| EN ISO 18273 | Al 5356 (Al Mg5Cr(A)) |

|---|---|

| AWS/SFA-5.10/5.10M | ER 5356 |

| UNS | A95356 |

| ISO TR 17671-4 / EN 1011-4 | Type 5 |

| ASME IX | F-Nº22 (QW-432) |

Approvals

| Vd TÜV 1153 | DB N. 61.254.01 | CE N. 0035-CPR-C616 |

|---|

Chemical composition (weight %)

Chemistry according to EN ISO 18273. Individual values indicated in the table are maximum values.

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0,25 | 0,40 | 0,10 | 0,05 - 0,20 | 4,5 - 5,5 | 0,05 - 0,20 | 0,10 | 0,06-0,20 | 0,0003 | Rest./Bal. |

Mechanical properties, typical as weld

Mechanical properties of the deposited metal are determined by the dilution with the base material.

| Gas | Temp. | Condition | Yield Strength 0,2% | Tensile Strength | Elongation | |

|---|---|---|---|---|---|---|

| Values acc. to DIN 1732-3 | I1 | 20ºC | As welded | ≥ 120 N/mm2 | ≥ 250 N/mm2 | ≥ 18% |

Usual base materials to be welded

Suitable for joint welding of aluminium alloys from 5000 and 6000 series.

Packaging

| Product | Size (Ø mm) |

|---|---|

| Plastic spools, Baskets and Drums | GMAW 1-1.20 – 1. 60 GTAW 2.4-3.2 |

Storage

Keep protected from humidity and dirt. Once the package is opened, and in case of not using all the material, keep into its original case closed and preferably in a heated cabinet, at least at 20°C. Keep the label of the spool (GMAW) or wrapping (GTAW).

Before welding

Remove the alumina layer and dirt (grease, dust…) as well as humidity from the welding area mechanically or by brushing it with stainless steel spikes. Do not use lubricant that contains diluted oils in the joints.

Welding equipment

When welding GMAW, conducts (liners, etc.) and pushing rollers have to be suitable for aluminum and be kept clean. Do not hit the gas outlet nozzle.

Welding conditions

| Thickness | Temperature | |

|---|---|---|

| Preheating | ≥ 10 mm | Start : 90-110ºC |

| Interpass | All thickness | Max. 110ºC |

Shielding gas

Inert gas: Ar 100%, Ar-He mixture

EN ISO 14175: I1

Flow = 14-18 L/min

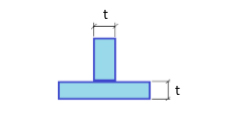

Welding positions

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| EN ISO 6947 | PA | PB | PC | PD | PE | PF |

| ASME IX | 1G | 2F | 2G | 4F | 4G | 3G ↑ |

Type of current & polarity

GMAW: Direct current, electrode to positive terminal: DC.E+ (Applicable modes: pulsed & not pulsed).

GTAW: Altern current, (Applicable modes: pulsed & not pulsed).

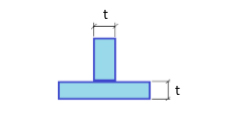

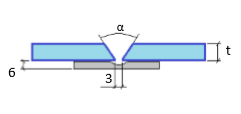

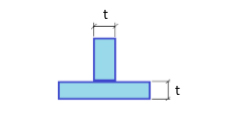

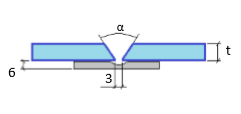

PRecommended welding parameters for GMAW (pulsed)

These parameters may vary slightly depending on the welding unit.

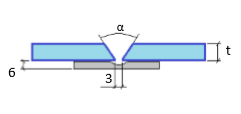

ø 1,0 mm

| Union | Param.* | Welding position | |

|---|---|---|---|

| All positions | |||

|

BW t ≤ 3mm | Int. (A) | 110-130 |

| Volt. (V) | 20-22 | ||

|

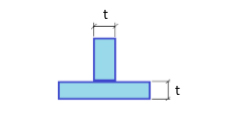

FW t ≤ 3mm | Int. (A) | 110-130 |

| Volt. (V) | 20-22 | ||

ø 1,2 mm

| Union | Param.* | Welding position | ||||||

|---|---|---|---|---|---|---|---|---|

| PA 1G | PB 2F | PC 2G | PD 4F | PE 4G | PF 3G ↑ | |||

|

BW mb t ≤ 3mm | Int. (A) | 140-150 | - | 140-150 | - | 140-150 | 130-140 |

| Volt. (V) | 21-22 | - | 21-22 | - | 21-22 | 21-23 | ||

|

BW mb t > 3mm t ≤ 8mm | Int. (A) | 160-180 | - | 150-170 | - | 150-170 | 140-160 |

| Volt. (V) | 22-24 | - | 21-23 | - | 21-23 | 23-24 | ||

| BW mb t > 8mm | Int. (A) | 180-220 | - | 170-180 | - | 180-220 | 140-200 | |

| Volt. (V) | 23-25 | - | 23-24 | - | 23-25 | 23-24 | ||

|

FW t ≤ 3mm | Int. (A) | 130-140 | |||||

| Volt. (V) | 21-23 | |||||||

| FW t > 3mm t ≤ 8mm | Int. (A) | 150-170 | ||||||

| Volt. (V) | 21-23 | |||||||

| FW t > 8mm | Int. (A) | 180-220 | 170-190 | 200-220 | 200-220 | 140-180 | ||

| Volt. (V) | 23-25 | 23-24 | 23-25 | 23-25 | 23-24 | |||

ø 1,6mm

| Union | Param.* | Welding position | ||||||

|---|---|---|---|---|---|---|---|---|

| PA 1G | PB 2F | PC 2G | PD 4F | PE 4G | PF 3G ↑ | |||

|

BW mb t > 5mm | Int. (A) | 280-330 --- | |||||

| Volt. (V) | 26-29 --- | |||||||

|

FW t > 5mm | Int. (A) | 280-330 | |||||

| Volt. (V) | 26-29 | |||||||

*Parameters for pulsed current.

Aluminium wire

Product description

Aluminium-Magnesium basis solid wire for GMAW and GTAW aluminium alloys welding.

Applications

Weldings where high tensile strength, high resilience resistance and excellent seawater corrosion resistance are needed. It can be applied in the construction of ships, railway, offshore and cryogenic plants.

Classification

| EN ISO 18273 | Al 5183 (Al Mg4,5 Mn0,7(A)) |

|---|---|

| AWS/SFA-5.10/5.10M | ER 5183 |

| UNS | A95183 |

| ISO TR 17671-4 / EN 1011-4 | Type 5 |

| ASME IX | F-Nº22 (QW-432) |

Approvals

| Vd TÜV 1153 | DB N. 61.254.01 | CE N. 0035-CPR-C616 |

|---|

Chemical composition (weight %)

Chemistry according to EN ISO 18273. Individual values indicated in the table are maximum values.

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0,40 | 0,40 | 0,10 | 0,50 - 1,0 | 4,3 - 5,2 | 0,05 - 0,25 | 0,25 | 0,15 | 0,0003 | Rest./Bal. |

Mechanical properties, typical as weld

Mechanical properties of the deposited metal are determined by the dilution with the base material.

| Gas | Temp. | Condition | Yield Strength 0,2% | Tensile Strength | Elongation | |

|---|---|---|---|---|---|---|

| Values acc. to DIN 1732-3 | I1 | 20ºC | As welded | ≥ 130 N/mm2 | ≥ 275 N/mm2 | ≥ 18% |

Usual base materials to be welded

Suitable for joint welding of aluminium alloys from 5000 and 6000 series.

Packaging

| Product | Size (Ø mm) |

|---|---|

| Plastic spools, Baskets and Drums | GMAW 1-1.20 – 1. 60 GTAW 2.4-3.2 |

Storage

Keep protected from humidity and dirt. Once the package is opened, and in case of not using all the material, keep into its original case closed and preferably in a heated cabinet, at least at 20°C. Keep the label of the spool (GMAW) or wrapping (GTAW).

Before welding

Remove the alumina layer and dirt (grease, dust…) as well as humidity from the welding area mechanically or by brushing it with stainless steel spikes. Do not use lubricant that contains diluted oils in the joints.

Welding equipment

When welding GMAW, conducts (liners, etc.) and pushing rollers have to be suitable for aluminum and be kept clean. Do not hit the gas outlet nozzle.

Welding conditions

| Thickness | Temperature | |

|---|---|---|

| Preheating | ≥ 10 mm | Start : 90-110ºC |

| Interpass | All thickness | Max. 110ºC |

Shielding gas

Inert gas: Ar 100%, Ar-He mixture

EN ISO 14175: I1

Flow = 14-18 L/min

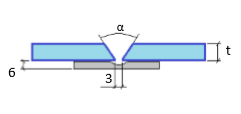

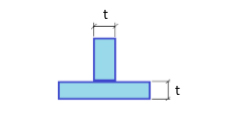

Welding positions

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| EN ISO 6947 | PA | PB | PC | PD | PE | PF |

| ASME IX | 1G | 2F | 2G | 4F | 4G | 3G ↑ |

Type of current & polarity

GMAW: Direct current, electrode to positive terminal: DC.E+ (Applicable modes: pulsed & not pulsed).

GTAW: Altern current, (Applicable modes: pulsed & not pulsed).

Recommended welding parameters for GMAW (pulsed)

These parameters may vary slightly depending on the welding unit.

ø 1,0 mm

| Union | Param.* | Welding position | |

|---|---|---|---|

| All positions | |||

|

BW t ≤ 3mm | Int. (A) | 110-130 |

| Volt. (V) | 20-22 | ||

|

FW t ≤ 3mm | Int. (A) | 110-130 |

| Volt. (V) | 20-22 | ||

ø 1,2 mm

| Union | Param.* | All positions | ||||||

|---|---|---|---|---|---|---|---|---|

| PA 1G | PB 2F | PC 2G | PD 4F | PE 4G | PF 3G ↑ | |||

|

BW mb t ≤ 3mm | Int. (A) | 140-150 | - | 140-150 | - | 140-150 | 130-140 |

| Volt. (V) | 21-22 | - | 21-22 | - | 21-22 | 21-23 | ||

|

BW mb t > 3mm t ≤ 8mm | Int. (A) | 160-180 | - | 150-170 | - | 150-170 | 140-160 |

| Volt. (V) | 22-24 | - | 21-23 | - | 21-23 | 23-24 | ||

| BW mb t > 8mm | Int. (A) | 180-220 | - | 170-180 | - | 180-220 | 140-200 | |

| Volt. (V) | 23-25 | - | 23-24 | - | 23-25 | 23-24 | ||

|

FW t ≤ 3mm | Int. (A) | 130-140 | |||||

| Volt. (V) | 21-23 | |||||||

| FW t > 3mm t ≤ 8mm | Int. (A) | 150-170 | ||||||

| Volt. (V) | 21-23 | |||||||

| FW t > 8mm | Int. (A) | 180-220 | 170-190 | 200-220 | 200-220 | 140-180 | ||

| Volt. (V) | 23-25 | 23-24 | 23-25 | 23-25 | 23-24 | |||

ø 1,6mm

| Union | Param.* | All positions | ||||||

|---|---|---|---|---|---|---|---|---|

| PA 1G | PB 2F | PC 2G | PD 4F | PE 4G | PF 3G ↑ | |||

|

BW mb t > 5mm | Int. (A) | 280-330 --- | |||||

| Volt. (V) | 26-29 --- | |||||||

|

FW t > 5mm | Int. (A) | 280-330 | |||||

| Volt. (V) | 26-29 | |||||||

*Parameters for pulsed current.

Aluminium wire

Product description

Aluminium-Magnesium basis solid wire for GMAW and GTAW aluminium alloys welding.

Applications

Excellent surface finish, very good weldability. Iron/metalwork, water conduction, electric elements.

Classification

| EN ISO 18273 | S Al 1070 (Al 99,7) |

|---|---|

| AWS/SFA-5.10/5.10M | ER 1070 |

| UNS | - |

| ISO TR 17671-4 / EN 1011-4 | - |

| ASME IX | EN AW-1070A |

Approvals

| CE N. 0035-CPR-C616 |

Chemical composition (weight %)

Chemistry according to EN ISO 18273. Individual values indicated in the table are maximum values.

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0,20 | 0,25 | 0,04 | 0,03 | 0,03 | - | 0,04 | 0,03 | 0,0003 | 99,70 |

Mechanical properties, typical as weld

Mechanical properties of the deposited metal are determined by the dilution with the base material.

| Gas | Temp. | Condition | Yield Strength 0,2% | Tensile Strength | Elongation | |

|---|---|---|---|---|---|---|

| Values acc. to DIN 1732-3 | I1 | 20ºC | As welded | - | ≥ 60 N/mm2 | ≥ 35% |

Usual base materials to be welded

Suitable for joint welding of aluminium alloy 1000. It can be used with alloys 5000 or other alloys whenever water tightness in the union is required or there are no mechanical requirements.

Packaging

| Product | Size (Ø mm) |

|---|---|

| Plastic spools, Baskets and Drums | GMAW 1-1.20 – 1. 60 GTAW 2.4-3.2 |

Storage

Keep protected from humidity and dirt. Once the package is opened, and in case of not using all the material, keep into its original case closed and preferably in a heated cabinet, at least at 20°C. Keep the label of the spool (GMAW) or wrapping (GTAW).

Before welding

Remove the alumina layer and dirt (grease, dust…) as well as humidity from the welding area mechanically or by brushing it with stainless steel spikes. Do not use lubricant that contains diluted oils in the joints.

Welding equipment

When welding GMAW, conducts (liners, etc.) and pushing rollers have to be suitable for aluminum and be kept clean. Do not hit the gas outlet nozzle.

Welding conditions

| Thickness | Temperature | |

|---|---|---|

| Preheating | ≥ 10 mm | Start : 90-110ºC |

| Interpass | All thickness | Max. 110ºC |

Shielding gas

Inert gas: Ar 100%, Ar-He mixture

EN ISO 14175: I1

Flow = 14-18 L/min

Welding positions

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| EN ISO 6947 | PA | PB | PC | PD | PE | PF |

| ASME IX | 1G | 2F | 2G | 4F | 4G | 3G ↑ |

Type of current & polarity

GMAW: Direct current, electrode to positive terminal: DC.E+ (Applicable modes: pulsed & not pulsed).

GTAW: Altern current, (Applicable modes: pulsed & not pulsed).

Recommended welding parameters for GMAW (pulsed)

These parameters may vary slightly depending on the welding unit.

ø 1,0 mm

| Union | Param.* | Welding position | |

|---|---|---|---|

| All positions | |||

|

BW t ≤ 3mm | Int. (A) | 110-130 |

| Volt. (V) | 20-22 | ||

|

FW t ≤ 3mm | Int. (A) | 110-130 |

| Volt. (V) | 20-22 | ||

ø 1,2 mm

| Union | Param.* | Welding position | ||||||

|---|---|---|---|---|---|---|---|---|

| PA 1G | PB 2F | PC 2G | PD 4F | PE 4G | PF 3G ↑ | |||

|

BW mb t ≤ 3mm | Int. (A) | 140-150 | - | 140-150 | - | 140-150 | 130-140 |

| Volt. (V) | 21-22 | - | 21-21 | - | 21-22 | 21-23 | ||

|

BW mb t > 3mm t ≤ 8mm | Int. (A) | 160-180 | - | 150-170 | - | 150-170 | 140-160 |

| Volt. (V) | 22-24 | - | 21-23 | - | 21-23 | 23-24 | ||

| BW mb t > 8mm | Int. (A) | 180-220 | - | 170-180 | - | 180-220 | 140-200 | |

| Volt. (V) | 23-25 | - | 23-24 | - | 23-25 | 23-24 | ||

|

FW t ≤ 3mm | Int. (A) | 130-140 | |||||

| Volt. (V) | 21-23 | |||||||

| FW t > 3mm t ≤ 8mm | Int. (A) | 150-170 | ||||||

| Volt. (V) | 21-23 | |||||||

| FW t > 8mm | Int. (A) | 180-220 | 170-190 | 200-220 | 200-220 | 140-180 | ||

| Volt. (V) | 23-25 | 23-24 | 23-25 | 23-25 | 23-24 | |||

ø 1,6mm

| Union | Param.* | Welding position | ||||||

|---|---|---|---|---|---|---|---|---|

| PA 1G | PB 2F | PC 2G | PD 4F | PE 4G | PF 3G ↑ | |||

|

BW mb t > 5mm | Int. (A) | 280-330 --- | |||||

| Volt. (V) | 26-29 --- | |||||||

|

FW t > 5mm | Int. (A) | 280-330 | |||||

| Volt. (V) | 26-29 | |||||||

*Parámetros para corriente pulsada.